DYNAMICS GROUP

MADISON HEIGHTS, MICHIGAN

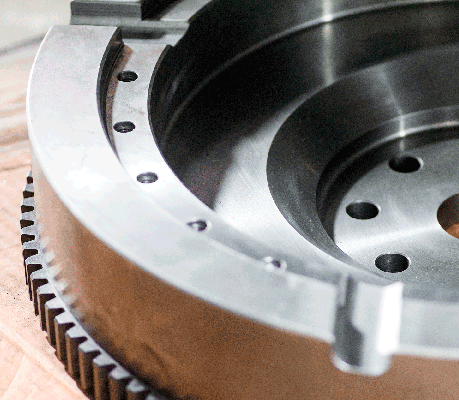

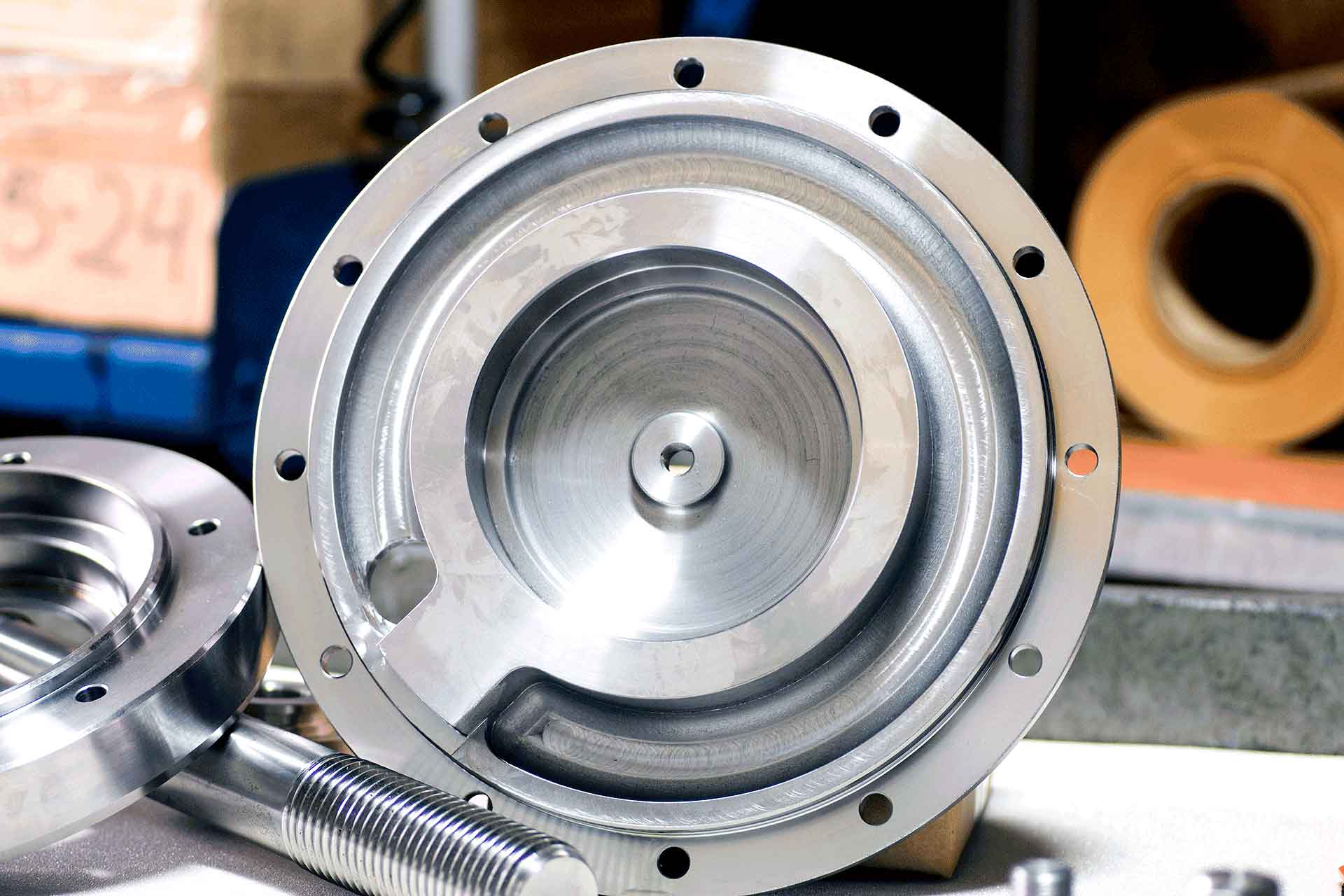

Dynamics Group is a design and manufacturing company. Our capabilities include designing, building, and integrating turnkey tooling solutions. Automotive weld line automation and the integration of several robotic fastener systems used by Caterpillar and others around the world. By injecting high-end automation, we have streamlined processes and expedited lead times for our customers!

Being vertically integrated allows the Dynamics Group to offer the design, rapid prototyping, fabrication, machining, assembly, inspection, and integration of tooling solutions components and assemblies. Our makeup lends itself to adding value to aerospace, energy, mining, and automotive through cost save analysis and rigorous engineering. Inside of our client portfolio includes high profile companies like Caterpillar, Continental, and Visioneering.

Differentiators:

- Strong focus on R&D to drive innovation and reduced costs within our offerings

- Fully integrated operation offering Design, Build, and Delivery

- Over 45 years of industry experience

Design services of Tooling, Prototype & Development, Factory Automation, Stress Analysis (FEA), Reverse Engineering, Product Simulation, 2D Layout, Shop Aids, Build Support, Lean Work Cells, Fully Automated Machines, Specialty Machines, Body in white automation

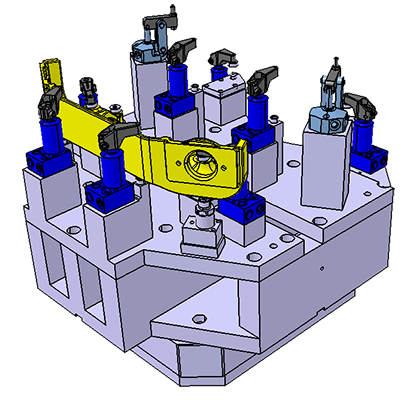

Tooling: Assembly & Bond Jigs, Layup & Mill Fixtures, Check Fixtures, Die Design, Location & Inspection Gauges

Manufacturing Solutions of CNC machining, CNC routing, Fabrication, Assembly, Inspection, Testing

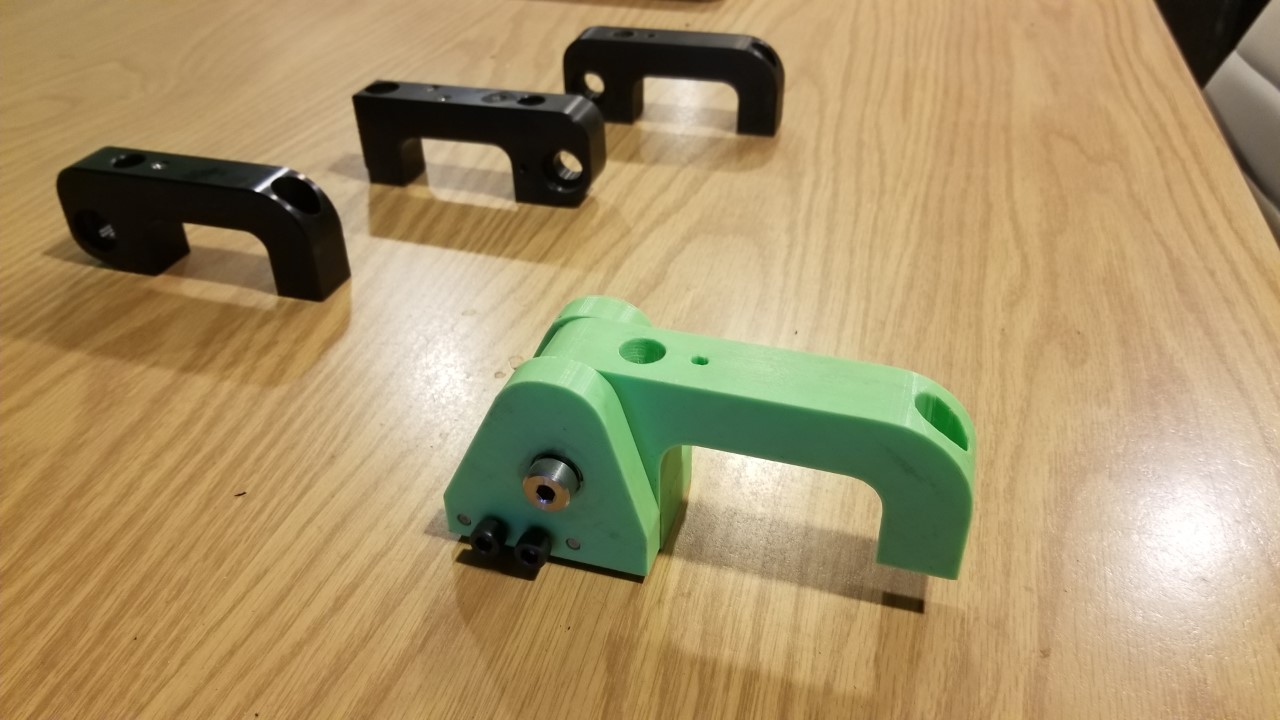

3D printing design optimization for prototyping of plastic and carbon fiber industrial tools and parts

Engineering Software: Fusion 360, AutoCad, Catia, SolidWorks

Fully System Integration

We have two 3D printers on site. A cubify cube pro and a mark forged X7

Cubify Cube Pro: prints PLA plastic

Applications

- Concept or design validation

- Testing form fit function

- Ergonomic Tools

- Assembly Trays

- Cosmetic Parts

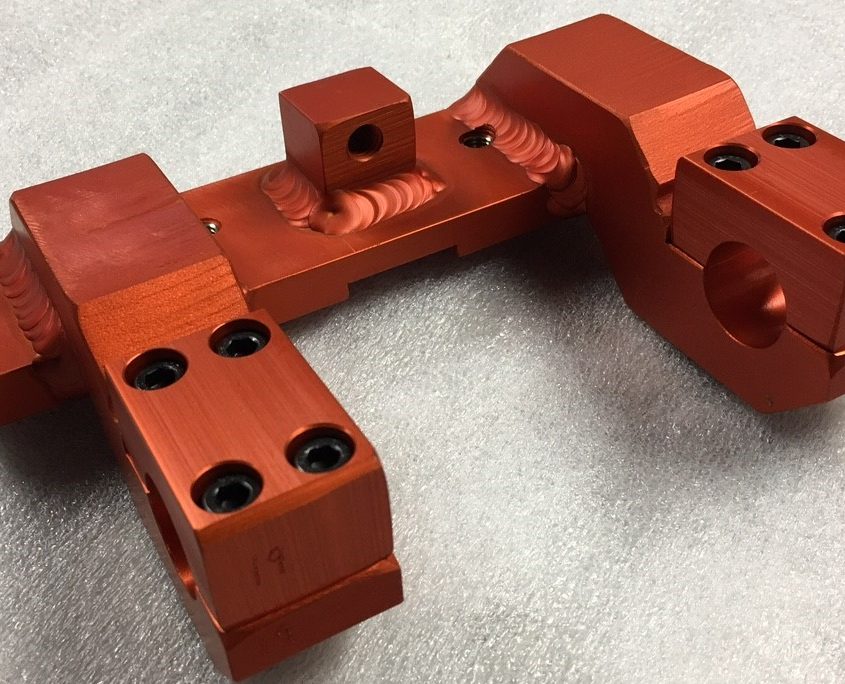

Mark Forged X7: prints carbon fiber (same material strength of 6061-T6 aluminum)

Applications

- High-Strength Tools & Fixtures

- Brackets & Mounts

- Inspection/CMM Fixturing

- Bespoke End-Use Parts

- Functional Prototypes

3D Printing Tools’ advantages are much shorter lead time (1-2 days) and cost (70% cost reduction) compared to machining and fabricating a tool. I have attached an informative write up from mark forged that is pretty good information about the current applications for 3D Printer capabilities.

Articles & News